Vacuum-packaging

1. Connect the bipolar plug, if 220V/240V, or the three-pole plug, if 380V/415V, to the current outlet.

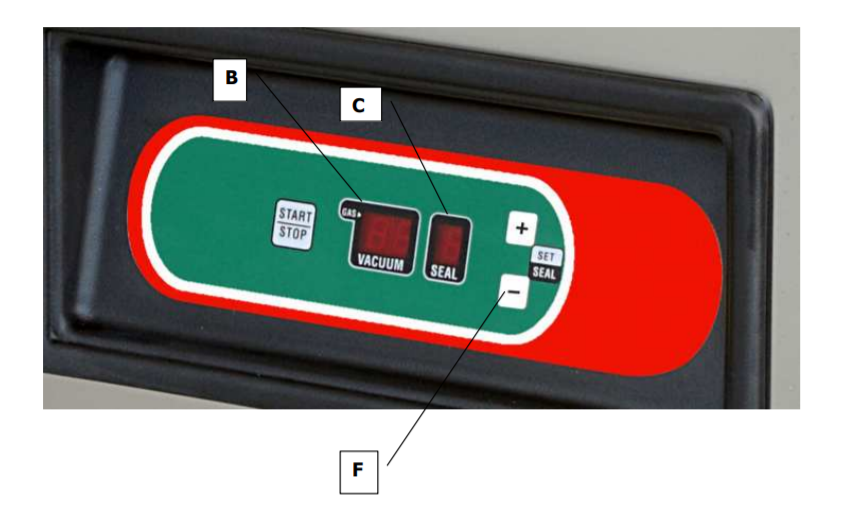

2. Press the line main switch 7 and the ON/OFF button thus connecting the electric circuit which supplies the modular card for the automatic cycle phases.

3. Set the vacuum time (or percentage) required, the sealing time and the gas injection time (if the machine is equipped with such a system).

4. Position the bag (or bags) inside the vacuum chamber; put the bag opening perfectly flat on the sealing bar. Put the exceeding part of the bag, if any, in the fissure between the chamber and the sealing bar.

5. Two or three removable food atoxic polyethylene shelves are positioned inside the vacuum chamber to level the product thickness according to the sealing bar. The polyethylene shelves can be removed or left inside the vacuum chamber depending on necessity..

6. Lower the bell-lid and press adequately on it until it remains closed, thus permitting the work cycle to begin.

7. The different cycle phases are fully automatic and, once achieved the percentage of vacuum setted, the bell can be opened again: the machine is now ready for a new cycle.